Continued from Dressing the Glimakra B2F Step 5: Tying Up the Lamms & Treadles

Remove the countermarch locking pins

|

| The locking pins keep the jacks (and everything else) from moving. |

The shafts shouldn't drop more than slightly.

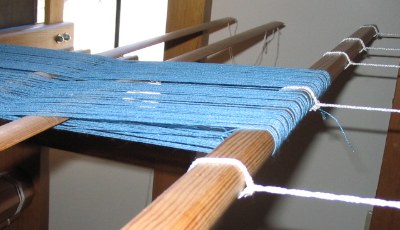

Evaluate the shed

This involves weaving a couple shots and then pressing each treadle in turn to check the levelness of the bottom of the shed.

|

| Adjustments needed on both bottom and top |

Fortunately, I took good notes on adjusting the shed the first time I set up the Glimakra. That post is here. Plus, I have Joanne Hall's Tying Up the Countermarch Loom (book review here). The summary of the process as follows.

- With locking pins in place, check:

- That the shafts are centered to the loom.

- That the warp runs through the center of the heddle eyes. If it doesn't, then the shafts need to be raised or lowered accordingly by adjusting the cord on the anchor pins on the jacks at the top of the countermarch.

- That the beater height allows the shed to run through the middle of the reed.

- That the lamms are level with one another. Adjust if necessary.

- Remove the locking pins

- Depress each treadle in turn and examine the shed.

- If all the warp ends are level, that's it.

- If some of them are above or below the others, make notes of which shaft they are on.

- To adjust the bottom threads of the shed:

- Start by adjusting treadle cords at the upper lamms. Use your notes.

- For shafts with warp threads that are too high, shorten the treadle ties.

- For shafts with warp ends that are below the shed, lengthen the treadle ties.

- Remove the locking pins and check again. Make more adjustments needed.

- To adjust the top of the shed:

- Adjust the treadle cords at the lower lamms, using your list.

- For threads that run too high, lengthen the treadle ties.

- For threads that run too low, shorten the treadle ties.

- Recheck and repeat if needed.

- Note that this is opposite of what was done with the upper lamms.

Note: Treadles don't have to be even in height.

Weave the header

Couldn't help but be a little nervous. Did I get my shed adjustments right? Did I make any threading mistakes? I caught a few when I sleyed the reed. Did I get the tension even across the warp? I'll find out now!

- Shed: good

- Treadle height: comfortable

- Fell line: straight

- Threading errors: the only "error" turned out to be a dropped treadle cord

- The ski shuttle worked well

Next time should go more quickly. For one thing, the shafts and lamms should need no further adjustment in the future. Plus, with this warp, I spent a lot of time researching, reading, re-reading, and comparing notes from various sources. For future reference, I have this blog series to refer to.

And with that, I'm ready to weave.

Dressing the Glimakra B2F Step 3: Winding on the Warp