When I read

this blog

the other day, I remembered my

silk goody pack. I was inspired to go get it out and look through it once more. I also pulled

out some dyed silk noils sent to me by my friend Heather, who lives in

Manitoba.

Heather does quite a bit of felting and fusion. A while ago

she had shared some information with the

Online Guild

about silk fusion. I had saved a copy of her instructions on my hard drive, so I

printed them out and gathered up my supplies:

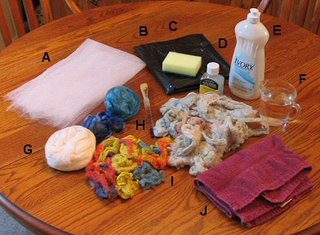

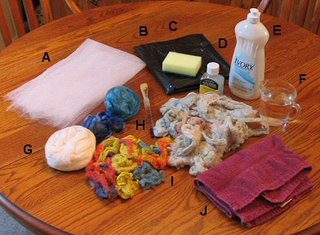

A - netting, B - plastic to cover my work surface, C - sponge for soaking up

excess water, D - acrylic gloss medium, E - dishwashing liquid, F - cup of

warm water, G - various silk tops, H - small, soft artist's brush, I - variety

of hand dyed silk noils, J - towel for hands, drips, whatever.

The

first step was to cut a piece of netting twice as large as the piece I was

going to make. The silk tops were drawn out to create two thin layers, the 2nd

perpendicular to the first:

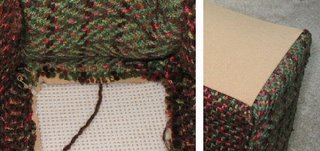

The netting was folded over and the entire thing wetted thoroughly with a

dilution of 1 teaspoon dishwashing liquid in 1 cup of warm water.

When thoroughly wet, the netting was lifted so that embellishments could be

added. Here I added some of the pastel silk noils:

After embellishing, the netting is folded over once again and the entire

thing rewetted. The sponge was used to mop up if I used too much water.

Next, a 50/50 mixture of acrylic gloss with water was brushed over the

entire thing.

Ideally, I should have had a drying rack or screen to place this on but I

didn't. I set it aside on a clean, dry towel and turned it occasionally.

I

had more of my acrylic mixture left, so I experimented:

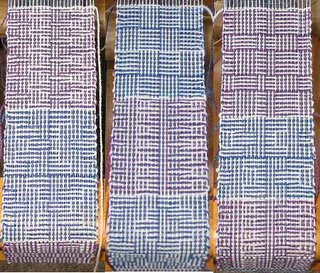

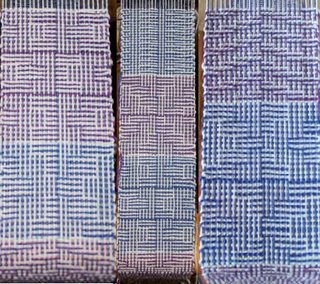

Left: I used my blue silk tops and embellished with some leftover

throwsters waste

which I had dyed.

Middle: Blue silk tops as a base embellished with silk noils.

Right: This

one is of silk noils entirely. I teased them out to make several layers.

I

allowed them all to dry overnight.

The next morning I carefully

peeled the netting off:

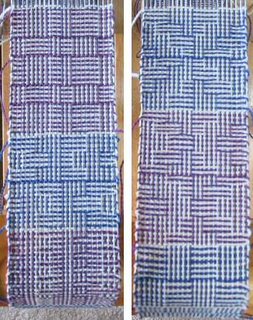

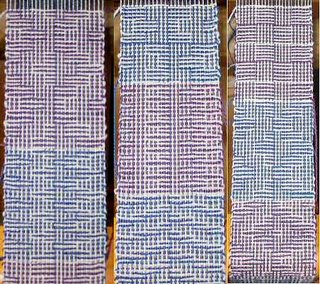

Here are my finished results:

I put the complete set of my silk fusion project photos on my

Flickr Photos.

At this point I have no plans for my masterpieces, except to

keep as samples or perhaps use as insets in greeting cards. I can see where I

made some places too thin and some too thick. There are some areas which could

have used more the the acrylic mixture, but even so I am happy with them.

These

were all quite spontaneous but I can see the potential for more thoughtful

designing. If you want to see some beautiful silk fusion and projects made

with it, spend some time exploring

Sue B's blog.

Her's are inspirational!

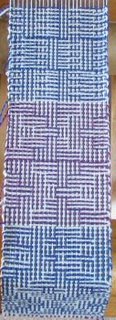

When I used to warp front to back, I would hand tension my warp. After

my first b2f warp, I decided to try using weights instead. When I did, I discovered that my warp

tension was more even and weaving was more enjoyable.

When I used to warp front to back, I would hand tension my warp. After

my first b2f warp, I decided to try using weights instead. When I did, I discovered that my warp

tension was more even and weaving was more enjoyable.