By

LeighI've already blogged about

ArahWeave and

WeaveDesign. The other day,

Laritza passed this one on to me; another weaving program that runs on

WINE. It 's freeware, it's from

Brunold Software, and it's called

DB-WEAVE.

I was doubtful at first, because the initial blurb states that it is for designing dobby loom patterns, but as I read on, I was delighted to discover that it also has a tie-up mode.

I got it up and running in WINE in no time. Like a lot of freeware, the help files are pretty much nonexistent.

[UPDATE 14 Dec 08 - Many thanks to

Frida, for alerting me to a pdf manual for DB-Weave. You can find it

here.]

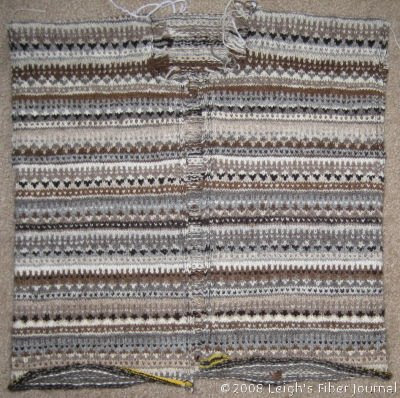

To explore the program, I inputted a draft from Shelp & Wostenberg's

Eight Shafts: A Place to Begin.

You can click on almost any photo to enlarge.

I have figured out that the red lines indicate the basic threading and treadling units. The drawdown highlights the intersection of these in red at the bottom right hand corner.

I found "Options" under the "Extras" menu.

These can be set as your default settings, or for individual drafts. You can see that "Sizes" sets the number of shafts, treadles, epi, and ppi. "Grid" overlays a grid on the draft, making it easy to keep your place. "Settings" allows you to choose single or multiple treadle modes (which I need for skeleton tie-ups and treadling!), and rising or sinking shafts. "Symbols" is for how the grid squares are filled in, and "View" lets you choose how draft is viewed on the screen.

The fun part is playing with the "Threading," "Treadling," and "Tie-Up" menus. (Click on any photo for a closer look-see.)

Threading options include mirroring, normal or straight rising and falling, 2 choirs (above), 3 choirs, fixed, user defined, and copied from treadling.

The Treadling menu includes mirror, normal rising and falling, crossed, fixed, and copy from threading (above, aka "tromp as writ" or "as drawn in."

Tie-up menu allows invert, roll (up, down, left, or right), and slope (increase [above] or decrease), or make central symmetric.

The draft view (above) can be with or without the drawdown. In addition, there is also.....

... color view, with the weaver's choice of warp and weft colors.

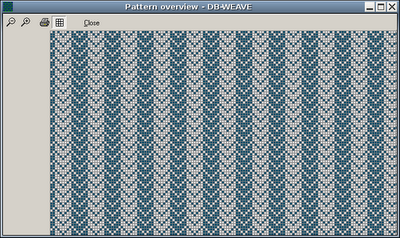

This is fabric view.

And overview.

Another feature I like is the undo and redo buttons! I don't have those with WeaveDesign. DB-Weave also imports and exports wif files (the standard format for most weaving software.)

Under the "Extras" menu, I also found .....

... pegplan mode. There's also a "weave" option in that menu which apparently tells the computer to talk to the loom. However, I don't have a dobby loom, nor are my computer and my Glimakra on speaking terms, so someone else will have to tell us all about that.

"Extras" also lets the weaver change the warp/weft ratio, and base setting for the program (choice of American, Scandanavian, or German/Swiss). Language options are English or German.

I haven't figured it all out yet, but I do find this program easy to experiment and play around with. I'm sure some of the menu options are dobby features. To me, it's the easiest free weaving software I've worked with so far. So for the moment, it's the one I'm going to stick with.

Related Posts:

Hurray for Hardy! Hurray for Wine! - WeaveDesign

Weaving Software for Linux - ArahWeave Part 1

ArahWeave Continued - ArahWeave Part 2

By Leigh

By Leigh Clickety on me!

Clickety on me! Me too.

Me too.