Enough of that and on to the fiber stuff.

Dan made it possible for me to attend the Southeastern Animal Fiber Fair (SAFF) over the weekend. It's been 2 years since I've been able to go so I was delighted to spend the day seeing old friends and immersing myself in all things fibery.

The drive to Asheville, NC was lovely. The weather was perfect and the autumn color, though just past peak, was still glorious.

This year's SAFF was the best I've seen. There were more vendors, more workshops, more demonstrations, more people, and less parking than before.

This is a shot of the inside of the main arena, where the vendors and workshops are. The workshops are held in the partitioned areas in the center, and vendors are packed into the different levels. The nice thing is that the arena is covered, so that rain isn't a problem.

This is a shot of the inside of the main arena, where the vendors and workshops are. The workshops are held in the partitioned areas in the center, and vendors are packed into the different levels. The nice thing is that the arena is covered, so that rain isn't a problem.I would have liked to have taken Eileen Hallman's point spinning workshop, but our transportation situation prevented me from knowing whether or not I'd have a vehicle for the weekend. As it was, it was a last minute spontaneous decision to go anyway.

Here is the Beginning Spinning workshop.....

..... I loved the spinning wheels and couldn't resist taking a pic.

..... I loved the spinning wheels and couldn't resist taking a pic.I went with a shopping list but didn't buy a lot. Typical for me, I got quite overwhelmed at all the beautiful fibers, yarns, tools, garments, projects, etc., and become exceptionally indecisive.

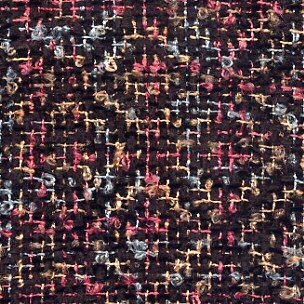

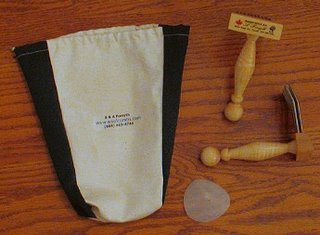

Some things I was looking for I found, other things I didn't. And I saw some things I wished I'd added to my list and planned on getting. I did buy more Cushings acid dyes and weaving bobbins. My luxury purchase was this......

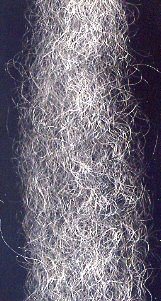

...... some clean California Variegated Mutant fleece from Delly's Delights Farm who traveled all the way from Trappe, MD. Now I'm trying to figure out how to squeeze it into my Rare Breed Sweater, for which I already have plenty of samples!

...... some clean California Variegated Mutant fleece from Delly's Delights Farm who traveled all the way from Trappe, MD. Now I'm trying to figure out how to squeeze it into my Rare Breed Sweater, for which I already have plenty of samples!We also had a chance to visit the barns. My favorite (besides the angora bunnies who were all in the main arena) is this......

I love alpacas. We were introduced to them at Alpaca Magic USA when we lived in Florida and my dream then was an Alpaca ranch............ which will probably always remain a dream. :)

I love alpacas. We were introduced to them at Alpaca Magic USA when we lived in Florida and my dream then was an Alpaca ranch............ which will probably always remain a dream. :)The best part of SAFF was getting to see friends. From the Blue Ridge Spinners I saw Carol, Mary, and Eva. From the Western North Carolina Fiber/Handweavers Guild I saw Betsy, Pat, and Charlene (though Mary and Eva are members of this too.) Betsy was my weaving teacher, so I was especially glad to visit with her. She is still just as encouraging as ever.

It's fun how an event like this can be so inspirational. It's refreshing as well as energizing. Now all I have to do is put that inspiration and energy to work.

© 2006 Leigh's Fiber Journal