For my first warp on the Glimakra, I decided to follow the steps on the set-up video. It used a back to front one cross method, which is what I've been using on my Schacht. However, it did a few things differently and I wanted to try these. For my first project, I wanted to weave a blanket for the WNCF/H Guild's service project, Project Linus. Until now, I hadn't had a loom able to weave the minimum 35 inch blanket width.

Of course on the set-up video, the loom is being warped for the first time, so the shafts are placed up on top of the countermarche, getting them out of the way for warping. Since my loom had already been woven on, the shafts were still tied to the lamms. After a little internal debate, I untied the lamms and put the shafts on top of the countermarche. I wasn't sure if this needed to be done for every new warp, but it let me follow along with the video more easily.

As you can see in the above photo, two long support sticks are placed on either side of the loom, resting on the front and back beams. The lease sticks and raddle rest nicely on these, making it easy to work with the warp and wind it on.

The raddle Dan made me for my Schacht isn't wide enough for this loom, but happily, I discovered that the top piece of my triangle loom worked very well, having enough length plus 1/2 inch spaces between the nails. After securing the warp with the lease sticks, I spread it out in the raddle.

The one cross b2f method I had been using was from Deb Chandler's Learning to Weave. It uses a threading cross only. In the Glimakra video, the cross is a raddle cross. No threading cross is used. The heddles are later threaded directly from the lease sticks.

The one cross b2f method I had been using was from Deb Chandler's Learning to Weave. It uses a threading cross only. In the Glimakra video, the cross is a raddle cross. No threading cross is used. The heddles are later threaded directly from the lease sticks.

In Chandler's method, an extra (lease) stick is placed in the the back loop of the warp (the end without the threading cross). This stick is then tied to the back apron rod. In the Glimakra video, the warp is actually transferred to the apron rod. On the left you can see that an extra (warp) stick has been placed in the cross with the lease sticks. This stick enables transfer of the warp to the apron rod.

The first step was to lay out the back apron cord and the warp, making sure both were centered. The warp was positioned so that it was divided into equal parts, each part to be placed between the corresponding apron cords.

The raddle Dan made me for my Schacht isn't wide enough for this loom, but happily, I discovered that the top piece of my triangle loom worked very well, having enough length plus 1/2 inch spaces between the nails. After securing the warp with the lease sticks, I spread it out in the raddle.

The one cross b2f method I had been using was from Deb Chandler's Learning to Weave. It uses a threading cross only. In the Glimakra video, the cross is a raddle cross. No threading cross is used. The heddles are later threaded directly from the lease sticks.

The one cross b2f method I had been using was from Deb Chandler's Learning to Weave. It uses a threading cross only. In the Glimakra video, the cross is a raddle cross. No threading cross is used. The heddles are later threaded directly from the lease sticks.In Chandler's method, an extra (lease) stick is placed in the the back loop of the warp (the end without the threading cross). This stick is then tied to the back apron rod. In the Glimakra video, the warp is actually transferred to the apron rod. On the left you can see that an extra (warp) stick has been placed in the cross with the lease sticks. This stick enables transfer of the warp to the apron rod.

The first step was to lay out the back apron cord and the warp, making sure both were centered. The warp was positioned so that it was divided into equal parts, each part to be placed between the corresponding apron cords.

One thing that was different with the way my loom is set up, is that the apron cords are not continuous lengths of cord looped over the apron sticks. The previous owner had cut the apron cords into equal lengths, and tied these onto the apron sticks from the warp and cloth beam. You can get an idea of this in the above photo.

Had these been looped over the apron stick as one long cord, I would have been able to transfer the loops of the cord onto my arm. However, since I was dealing with individual lengths of cord, I had to remove them from the stick in order to transfer the warp.

Had these been looped over the apron stick as one long cord, I would have been able to transfer the loops of the cord onto my arm. However, since I was dealing with individual lengths of cord, I had to remove them from the stick in order to transfer the warp.

I took my own photos, so you can't see that this is really a 2-hand task. I found that after deciding where the groups of warp needed to be placed on the apron rod, it was easiest to tie them onto bundles. Starting in the middle, I removed the apron cords from the apron rod until I got to the place for warp bundle I wanted to transfer. After I put the bundle onto the apron rod, I pulled the temporary stick out, replaced the apron cord and then moved on to the next bundle. I did this in two halves, working from center outward, since my warp is so wide.

After all the bundles of warp were transferred from the temporary stick to the apron rod and the cords replaced, I spread the warp out between the apron cords. The lease sticks remain in the warp to hold the cross.

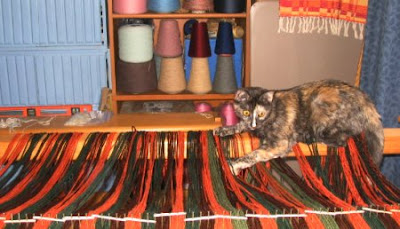

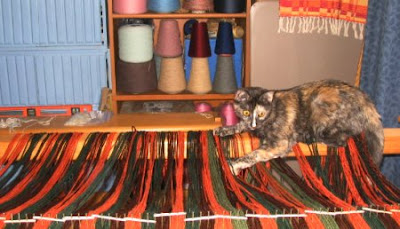

Since my warp is so wide, and I don't have enough 1/2 gallon milk jugs / weights, I tensioned the warp myself as I wound it on. I did have help . . .

Since my warp is so wide, and I don't have enough 1/2 gallon milk jugs / weights, I tensioned the warp myself as I wound it on. I did have help . . .

. . . but as you can see, it wasn't the useful kind.

I found that by using Peggy Osterkamp's "firewood method" (picture here), I could put my full body weight into it. Hopefully I have it tensioned evenly!

The loom also came with warp separator sticks. The previous owner's husband made this very handy storage container for them . . .

I found that by using Peggy Osterkamp's "firewood method" (picture here), I could put my full body weight into it. Hopefully I have it tensioned evenly!

The loom also came with warp separator sticks. The previous owner's husband made this very handy storage container for them . . .

The sticks are flexible enough to remove easily from the container through the long oblong opening.

After I finished winding on, the breast beam and knee beam were removed. The bench fits nicely inside the loom and I'm ready to take the shafts down from on top of the countermarche and start threading the heddles.

After I finished winding on, the breast beam and knee beam were removed. The bench fits nicely inside the loom and I'm ready to take the shafts down from on top of the countermarche and start threading the heddles.

Next, threading.

Related posts:

New Loom

Why A Countermarche?

Warping the Glimakra:

.....Adjusting the Loom With Texsolv

.....Threading

.....Tying Up the Treadles

.....The 3 Duhs

.....Adjusting the Shed

....

© 29 June 2007 at http://leighsfiberjournal.blogspot.com

Related posts:

New Loom

Why A Countermarche?

Warping the Glimakra:

.....Adjusting the Loom With Texsolv

.....Threading

.....Tying Up the Treadles

.....The 3 Duhs

.....Adjusting the Shed

....

12 comments:

Very nice!

Interesting placement of raddle. I put mine on the back beam, the lease sticks in front of it so that the cross ends up right behind the heddles. I'm waiting for the threading to see how you do this. Also, I assume the lease sticks are put through the raddle cross, but how will you know which thread to pick first, second and so on? Perhaps this will become clear. Finally, I like the way you attach the warp to the back beam. I may try that, though I'm not sure how to string the cord over my arm!

Hi Leigh,

it's all looking good so far!

I'm surprised about moving the shafts out of the way to warp. On my countermarche (a Toika) I push the heddles to either side and leave the shafts in place. This allows plenty of space.

I'm impressed by the size of your loom and the space your have to work in for threading up. My loom is very compact and it's a good thing I'm a small person as I have to fit in some uncomfortably small spaces!! Your Glimakra looks like a luxury model to me - you are lucky!

Re. tying on at the back, I use a 2nd rod lashed to the apron rod. This means that I can thread my 2nd rod through the loops in the warp and then lash it to the apron rod after, you might find this simpler and quicker than untying and re-tying the apron strings. When I lash the two rods together I lay then next to each other on the back beam so they are supported and I can easily tie them with equal length ties. I use plenty of ties and prefer linen warp thread for them as it is strong and doesn't stretch.

I don't bother with a 2nd apron rod at the front though, it didn't seem to give any advantage.

I've taken photos of my texsolv treadle tie up which i shall e-mail to you, I was spending ages tying up treadles at first but then after discussions with other weavers I changed the whole system. I can now tie my 8 shafts & 10 treadles in 30 - 40 minutes (it took about 4 hours before!)

The class I took taught BtoF but somehow I've gotten switched to FtoB. It's awesome to see what you're doing just the same. I do think that any kind of technical weaving probably has to be warped the way you're doing it. Since I weave with my handspun, I probably will continue to warp as I do now. I love Syne Mitchell's into to her podcast - "you have to be warped to weave" - can't start without warp, however you put it on.

Thank you so much for your encouraging and helpful comments. Actually I need all the help I can get!

Peg, I had noticed your raddle placement from that photo on your blog and was mostly struck that you had it on it's side rather than straight up. Your long nails look very useful. I simply put my raddle where she put it in the set-up video. Glimakra makes a raddle that sits in the beater as well.

Dorothy, I'm so glad to know that about warping with the shafts still in place. I think that will be easier in the long run. Regarding the apron strings, I didn't have to untie them. They are texsolv strings which are looped on themselves. All I had to do was slip them off the rod and then slip them back on again.

Sharon, I may be knocking on your door when I start to weave with my handspun! That is something I don't have a clue about!

Oh Leigh, boy do I have blanket weaving envy! Would love to have a floor loom wide enough to do one! Ah well, will live vicariously through your projects!

Well done!

Leigh, I have only used F2B so far, and am in awe of your method of B2F. And I am just dying to do a blanket...

Cheryl and Rob, I'm not so sure I should have chosen a blanket as my first project on this loom. We'll see how it goes. I took a class in double weave several years ago but wasn't able to master a smooth fold. It will be something else to work on in the future for really large blankets.

Seeing your pictures makes me want to set up my loom again.

Great post! And I feel your bad cat pain, I have a furry heathen who just can't resist a good warp.

The look on your cat's face is priceless! Thanks for the great series of posts!

Well, Christine and Ellie, she was getting a good fussing at, but didn't care one bit!

Janet, by all means set up your loom again!

Post a Comment