I first learned how to tie on when I was warping front to back (f2b). When I warped f2b, my warp was tied to the back apron rod in bundles. Warping back to front (b2f) is a little different. The warp isn't cut for the back apron rod, rather the apron stick is slipped through the uncut loop at one end of the warp.

This makes tying on a little challenging. Once the weaving is cut off the loom, the remaining warp is no longer secured because it isn't tied to the apron rod. It can easily be pulled off. When I tie on a new warp, I'm careful to not pull the old warp ends off, but they do become very uneven from my pulling and tying. No matter how careful I am, I end up with uneven lengths of warp.

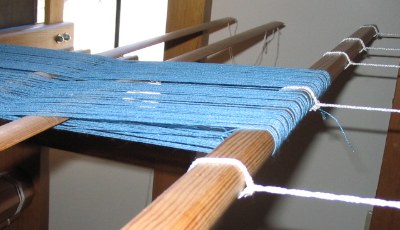

I was thinking about this as I finished weaving my advancing twill sample warp. My plan was to tie on a different size yarn and experiment with that. So to secure the old warp, I decided to see if I could weave in an inch or so of waste weft, close to the back apron rod to hold the warp in place.

To do this I needed tension on the warp, so I waited to cut off the woven fabric. First I pulled the lease sticks out, and then from the back of the loom, pushed the treadles down to make a tabby shed. It was pretty awkward, but I was able to weave in about four picks of a heavy yarn. I beat them down with a hair pick and then put the lease sticks back in the same way.

I was thinking about this as I finished weaving my advancing twill sample warp. My plan was to tie on a different size yarn and experiment with that. So to secure the old warp, I decided to see if I could weave in an inch or so of waste weft, close to the back apron rod to hold the warp in place.

To do this I needed tension on the warp, so I waited to cut off the woven fabric. First I pulled the lease sticks out, and then from the back of the loom, pushed the treadles down to make a tabby shed. It was pretty awkward, but I was able to weave in about four picks of a heavy yarn. I beat them down with a hair pick and then put the lease sticks back in the same way.

I found that this helped stabilize the warp quite a bit; though not enough to prevent it from being pulled out if I tugged hard enough. Even so, it helped a lot. The next time I tie on, I'll weave in a bit more and that should do the trick.

© 2008 Leigh's Fiber Journal

5 comments:

Cleverness!

I missed your original post about tying a new warp to the old, thanks for coming back to this topic.

What puzzles me about this technique is I always use lots of ties wrapped around my warp to keep all the threads together and at the same tension. I think that if I then tied my new warp to the old, the knots for doing this would be in slightly different places and my ties designed to maintain the warp threads at same tension would then be kind of irrelevant?

Dorothy, I have thought about trying to tie the warp at the back apron rod but wasn't sure how well it would work. I might have to give this a try next time.

Leigh, I'm not quite sure I understand the problem. I tie those half knots on groups of warp ends in front of the reed or heddles. No slipping around on back beam. And when I tie on there ends up some unevenness anyway, at least with my imperfect knotting technique. But winding on seems to get everything even. Also, you're probably going to have to spread the warp out some if you are using a fatter yarn since a fatter yarn would need a wider sett.

YOu could always use masking tape to tape your warp to that nice fat wooden apron rod. I've seen people do this when making a warp with fishing line with good results.

Post a Comment