Summer is a busy month for the garden and outdoor projects. But I still take time every day for some fiber and textile play. At the moment, that's been fleece prep and spinning.

For spinning, I'm still working on the beautiful

Shetland roving gifted to me. Spinning isn't exactly something one forgets, but I did have to practice a bit to re-learn the right treadle pressure, rhythm, wheel tension, and best amount of twist (still working on that one).

I got my first bobbin filled, and wanted to ply it from a

center pull ball. But my ball winder is missing the thumb screw that attaches it to a table. I'm sure it's around somewhere, but in the meantime, I decided to try my hand with a nostepinne.

A nostepinne is a Norwegian tool for winding yarn into center pull balls. It's basically a tapered dowel, often with a notch or two. It looks something like this.

This isn't a true nostepinne, but rather a pirn for an

end feed shuttle. It's not as thick as the nostepinnes I've seen demonstrated on YouTube, even though I've seen pirns like this being sold on Etsy as nostepinnes. It's what I have, so I decided to give it a try. For a first ball, I'm calling it "not bad," with room for much improvement.

I'll let you know how the plying goes.

My other fiber project has been completing the requirements for a

textiles merit badge at permies.com. I've blogged about these virtual badges before, and what makes them fun, is the challenge of accomplishing a skill. This badge requirement is for preparing 8-ounces of sheep wool for spinning. So it's been a great way to get back into the swing of things.

Here are my documentation photos.

|

| unwashed fleece |

Unfortunately, I'm not sure what breed this is from. It was stuffed into a large trash bag and once upon a time was labeled with a piece of masking tape. Alas, that fell off, so I'm clueless, which is too bad because it's a lovely fleece.

|

| skirting, sort of |

Since it was a jumble, it's hard to tell what's what. But I picked out all the dirty bits and second cuts, and sorted it according to crimp and length.

|

| scouring |

This fleece had been in storage for probably 20 years, so the lanolin was pretty hard! One good point about storing it in the grease was that fiber moths never touched it.

|

| washed and dried |

The requirements call for preparing half-a-pound, so here's 8 ounces of it, washed and weighed out.

To prepare for spinning, I decided to use my hand cards. This is primarily because my drum carder needs its belt replaced. But since the badge requires that I state why I chose my processing method, I'll add that the crimp and staple length recommend it for woolen spinning. Hand carding is a traditional prep for this, so hand carding is a good choice.

I will say that the tips were still a little stiff, so I used my bunny dog comb to open them up before loading the hand cards.

It was nice that it only took a little practice to feel like I know what I'm doing again. It's slow going, however, (relaxing) so I'm listening to Anna Karinina from the Internet Archive while I work. I like the reader so it's all very pleasant.

I'm not quite done yet, but my basket of rolags is growing!

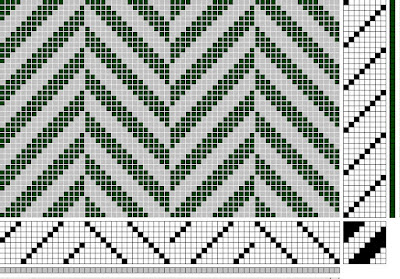

After I finish this, I'll get back to finishing my evolving pumpkin heads sampler and start measuring warp for the next project for my floor loom.