My 4th set of lace weave samples for the Beginning Lace Weaves Workshop, is off the loom. These samples are Spot Bronson which, although aren't technically lace, gives us the background for Bronson Lace.

The draft is from Marguerite Porter Davison's A Handweaver's Pattern Book. It is the Rose Point Pattern in the Barley Corn Weave chapter, page 86. Barley Corn is another name for Spot Bronson. I used the same 12/2 cotton warp, but experimented with two different weft yarns. The rose point pattern has 2 variations, so I ended up with 4 samples.

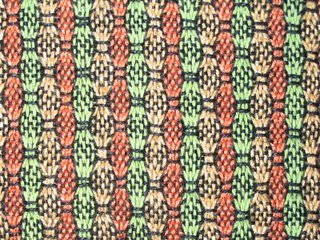

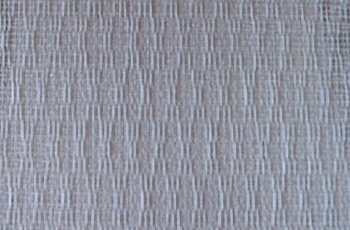

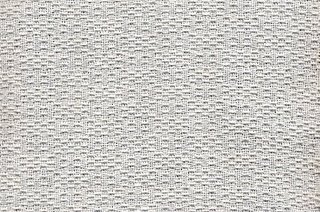

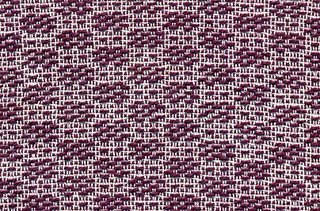

For the first weft, I used a 3/2 mauve cotton for the pattern and the same 12/2 cotton for the tabby weft.

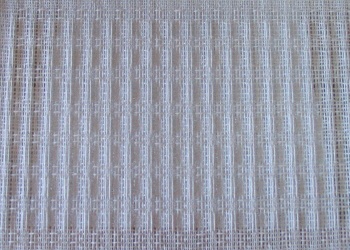

Then I tried it using only the white 12/2 cotton. It's hard to see the pattern......

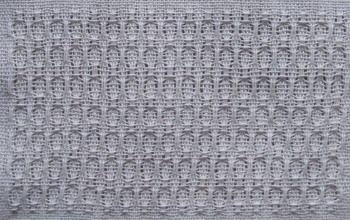

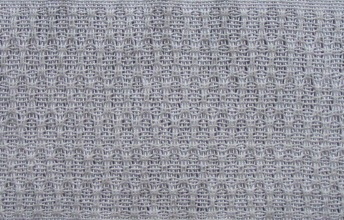

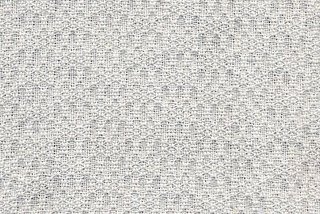

Then I tried it using only the white 12/2 cotton. It's hard to see the pattern...... ..... in fact, I like the backside better........

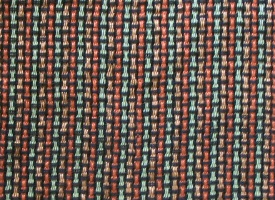

..... in fact, I like the backside better........ I used the same weft yarns for the 2nd variation:

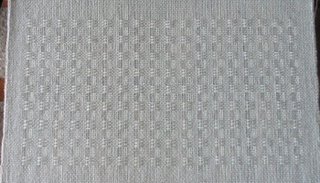

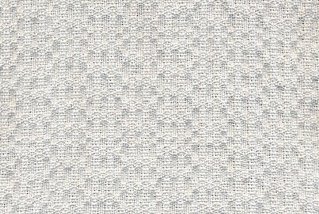

I used the same weft yarns for the 2nd variation: Front in all white:

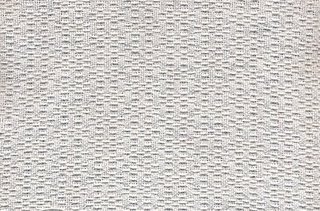

Front in all white: And back:

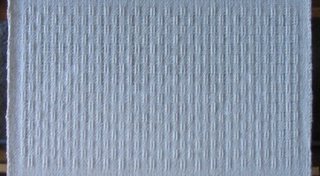

And back: What you can't see in these photos is the sculptured effect the white samples have, which I think is very nice! In fact it is this texture which has given me some ideas of where to place stripes of color, giving plenty of experiments to store away for future use.

What you can't see in these photos is the sculptured effect the white samples have, which I think is very nice! In fact it is this texture which has given me some ideas of where to place stripes of color, giving plenty of experiments to store away for future use.© 30 Nov. 2006 at http://leighsfiberjournal.blogspot.com

Related Posts:

Lace Sampler - Beaming the Warp

Lace Sampler - Huck

Lace Sampler - Huck Lace 1

Lace Sampler - Huck Lace 2

Lace Sampler - Lace Bronson