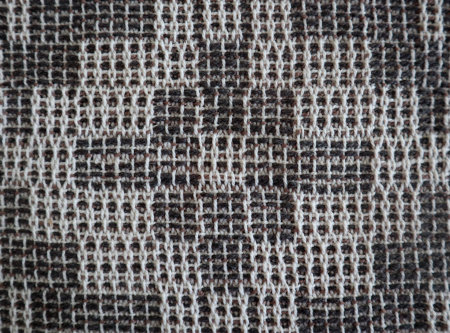

All of my blogs are topical, which means if I'm not doing anything related to that topic then I rarely post. That said, I did have quite a few fibery plans this summer, none of which materialized other than thinking about them. I wanted to do a lot more natural dyeing, I (still) have my big and little brother blankets to weave, I wanted to spin some lovely fleece that I have, and I hoped to do my Weaving My Family Tree project.

Instead, it's been a busy summer picking garden produce and processing it, more so it seems than last summer. Then Dan decided to start the renovation project in my loom room, which meant everything had to be covered for dust protection. Plus my sewing room, where my table loom lives, is the hottest room in the house so it's not very conducive to spend time there. I have gotten a little mending done.

The genealogy weaving actually took an alternate path in that it became a cooking project. I somehow got off on researching the cultural cuisines of my ancestors and I've been tracking down and cooking recipes to make period meals. I'm still working on it and it's been both fun and interesting. I will still do the historical weaving one of these days and perhaps put it all together in a family history book for my kids some day.

Of the blankets, Dan will hopefully not take long with his renovation project. I'd like to have the blankets done for Christmas! But that's out of my hands (as is so much of my life anyway.) 😀